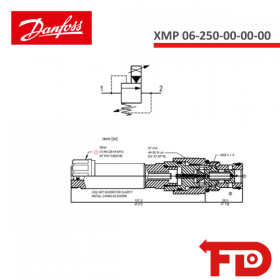

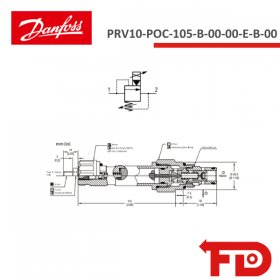

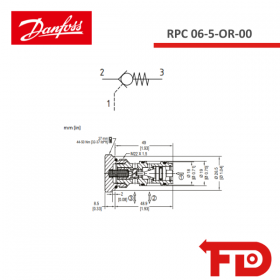

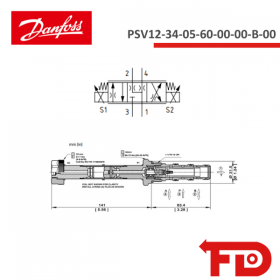

850179719 - RELIEF VALVE XMP 06-250-00-00-00 - DANFOSS

Proportional Relief Valve, Spool Type, Pilot Operated, Normally Open

315 bar [4500 psi] • 50 l/min [13 US gpm]

DESCRIPTION AND OPERATION

This is a pilot operated, spool type, normally open, proportional relief valve. In the de-energized condition, the pressure setting will be at a minimum. As current is applied to the coil, the pressure setting of the valve will increase proportionally. This valve is ideal for system pressure control where flows may vary

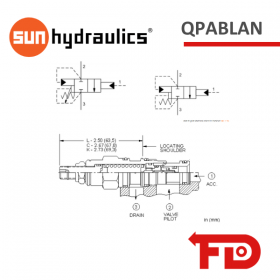

315 bar [4500 psi] • 50 l/min [13 US gpm]

DESCRIPTION AND OPERATION

This is a pilot operated, spool type, normally open, proportional relief valve. In the de-energized condition, the pressure setting will be at a minimum. As current is applied to the coil, the pressure setting of the valve will increase proportionally. This valve is ideal for system pressure control where flows may vary