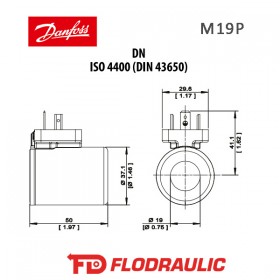

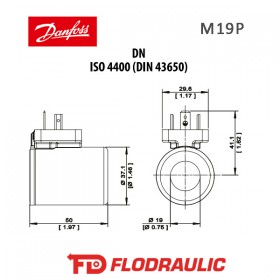

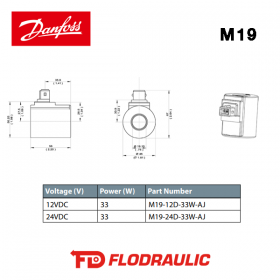

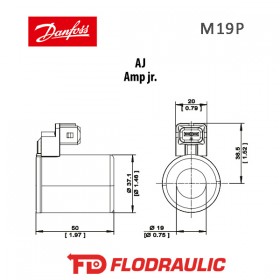

171132519 - COIL M19P-12D-1.8A-DN - DANFOSS

Coils and Electrnics

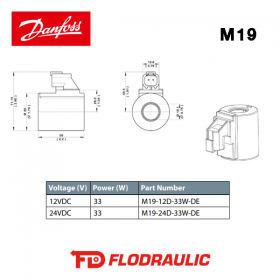

M19 - 22W Proportional Coil

PERFORMANCE DATA:

Magnet wire insulation: 200°C [392°F]

Maximum Continuous Current: 1.8 A [at 12V] 0.9 A [at 24V]

Ambient temperature range: -20 to 40°C [-4 to 104 °F]

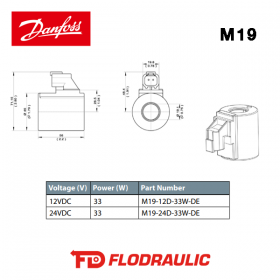

M19 - 22W Proportional Coil

PERFORMANCE DATA:

Magnet wire insulation: 200°C [392°F]

Maximum Continuous Current: 1.8 A [at 12V] 0.9 A [at 24V]

Ambient temperature range: -20 to 40°C [-4 to 104 °F]